What is the Purpose of CNC Machines?

The purpose of CNC machines is to carry out the process together with computer systems by throwing the physical power of the human into the background. This machine, which is generally needed in production facilities, is an important factor in paving the way for mass production. It makes the production that a person cannot do on a daily basis automatically, thanks to the programs it has. It is one of the machines that all companies and factories need most. It is a machine that both increases production and saves time. If we specify other purposes and features, we can list them as follows;

- It is indispensable for mass production.

- It can produce many times more than the amount of goods a human would produce.

- It can be easily adapted and used for any job by mounting on the bench and making the necessary programming.

- You can produce tens or hundreds of goods within minutes by making the necessary coding with these machines.

How Does CNC Machine Work?

Common machine tools that can work with CNC include:

- Lathe,

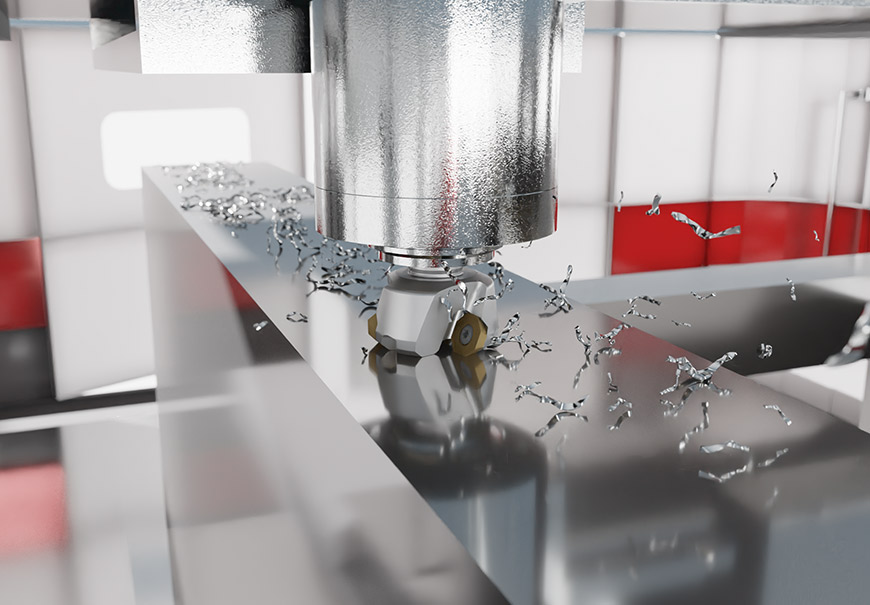

- Milling machines,

- Drilling Machine etc.

The main purpose of these machines is to remove some of the metal to give it the appropriate shape, such as round or rectangular. In traditional methods, these machines are used by expert operators. Jobs need to be handled accurately and the operator must be skilled enough to handle precision work.

In CNC machines, the role of operators is minimized. Here the operator only has to feed the instruction program on the computer and load the necessary tools into the machine. The rest of the work is done automatically by the computer. The computer directs the CNC machine to perform various machining operations according to the instruction program given by the operator.

All CNC machines are designed to meet very close accuracies. In fact, CNC machine is essential for most precision work.

And when you're done, you don't even need to uninstall it. The machine does the necessary work for you and does the next job itself within its program. In this way, your machine can continue production work 24 hours a day without needing to follow up too much. However, the control of the necessary programs and the supply of raw materials should not be forgotten.