What is CNC Machining Center?

CNC machining center is an advanced manufacturing machine that can perform machining operations with high precision and high surface quality. A CNC machining center can perform many operations such as drilling, milling and turning.

Before CNC machining centers were produced, this manufacturing process had to be divided into many working stages. This meant processing on different machine tools. Therefore, the delivery time was getting longer and the cost was increasing. CNC machining centers were developed to overcome these problems.

These machines; It is designed to handle milling, turning, drilling, and a variety of other machining needs.

CNC machining center can be classified according to a configuration as:

- Horizontal CNC machining center

- Vertical CNC machining center

- Universal CNC machining center

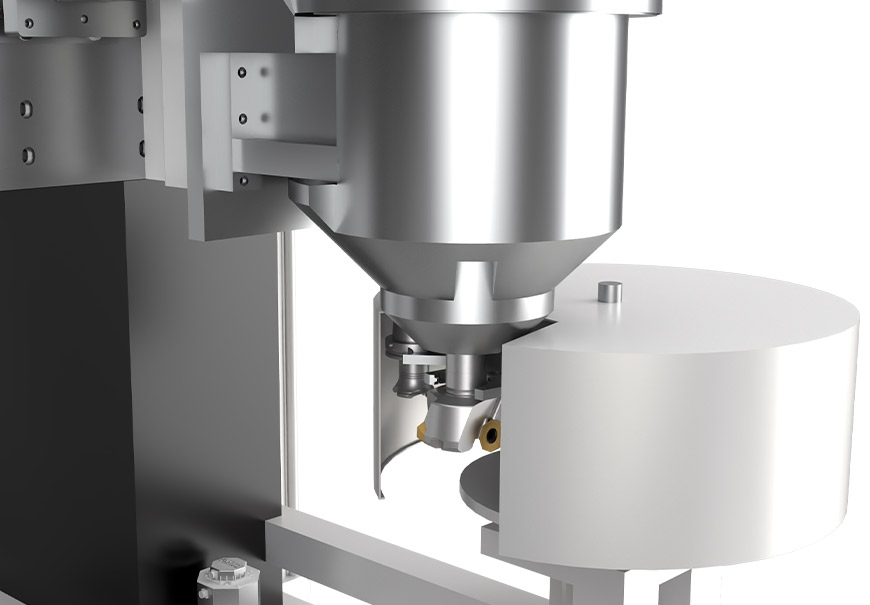

Horizontal CNC Machining Center:

The machining center has a horizontal spindle. The tool is mounted on the spindle of the machine. It consists of an interchangeable system that can store multiple tools and can hold a capacity of 16 to 100 tools.

Different programs may be required for different workpieces. Due to the high metal removal rate in the process, the cutting tool volume is usually large. The tool magazine therefore requires a large position on each tool.

Vertical Machining Center:

In vertical machining centers, multiple jobs can be done with a single setup. Vertical machining centers usually have three axes. Some have a spindle head function that can be rotated in one or both axes. It is most suitable for the mold and mold processing industry.

Universal Machining Center:

The universal machining center is similar to the “Horizontal Machining Center”, but the spindle can continuously switch from horizontal to vertical position under computer control.

It consists of five or more axes, which allows the upper surface of the workpiece to be mounted on a horizontal machining center, so that different sides of the workpiece can be machined in a single unit.