What are the CNC Machine Types?

CNC Machine Types

- CNC Lathe Machine

- Milling CNC Machine

- Drilling CNC Machine

- CNC Machine Grinding

- Laser Cutting CNC Machine

- Plasma Cutting CNC Machine

What Does a CNC Lathe Machine Do?

They are computer-aided, advanced technology lathe machines that can perform chip removal by means of a cutting tool on a rotating part.

When it comes to what a CNC lathe is and how its benches work, it can be called vertical lathe or horizontal lathe depending on whether the part is connected vertically or horizontally to the workbench. In addition, CNC lathes are classified according to dimensions such as 6”, 8” or 10” according to the size of the chuck on which the part is placed.

If we count the main parts of CNC lathes, we can say that they consist of the main parts such as control unit, body and carrier slides, as well as equipment such as spindle and motor, hydraulic unit, chuck, counter center, turret, cutting fluid tank and chip conveyor.

When it comes to what it is useful for, it enables operations such as face turning as well as external and internal diameter turning operations. In addition, CNC lathes can easily perform operations such as drilling grooving, threading, tapping, knurling and cutting.

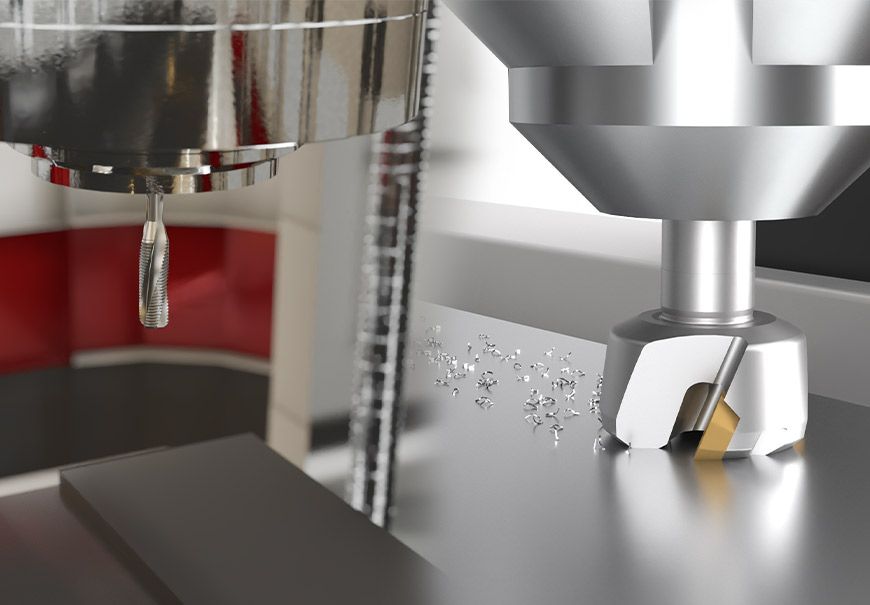

What Does a CNC Milling Machine Do?

This type of machine is used for processing flat and angled surfaces. In addition, it can be used for many purposes such as grooving, making straight and circular partitions.

Pros:

- It facilitates the processing of complex shapes.

- It enables identical parts to be produced from a single design, resulting in excellent repeatability.

- Since it uses computerized numerical control, it minimizes labor costs and increases productivity in the process.

Cons:

- CNC milling machines are expensive and have a heavy design.

- CNC machines should only be used by trained personnel.

- In case of malfunction, the repair cost is high and can cause loss of time.

Benefits and Features of CNC Drilling

CNC drilling is used to perform various drilling operations on the part surface. The benefits and features of CNC drilling can be listed as follows:

- CNC punching processes are frequently used in the production of high quality molds.

- Holes with a depth of 2600 mm and a diameter of 3-32 mm can be easily drilled.

- It can drill holes on complex machine parts as needed.

- It allows to perform the operation in a shorter time compared to traditional drilling operations.

- It is a machine using computer numerical control. It has the ability to produce highly precise and top-notch parts.

Pros:

- It offers high accuracy and excellent repeatability in manufacturing.

- It increases productivity thanks to its ability to drill in complex parts with high speed and extreme precision.

- Thanks to its lightweight design, it is often preferred in low-volume production.

Cons:

- Repair and maintenance processes are complex and costly.

- It has a limited cutting action.

What is CNC Grinding Machine?

CNC grinding machines have an automatic sharpening system. They are benches used for grinding the plane surfaces of workpieces. Horizontal or vertical spindle options are available.

What is CNC Laser?

CNC Laser is a device that uses special gases (Carbon Dioxide, Nitrogen, Helium, etc.) to create laser beams and performs 2-dimensional cutting, scraping and drilling processes, taking the cut of the desired shape from the computer environment and removing it exactly as desired.

The advantage of laser devices is that they can cut exactly as desired with zero deformation, as they cut with laser beam. Since there is no contact during CNC laser cutting, crushing or distortion does not occur in the material. Another important advantage is that since there is no roughening or burrs in the material, there is no need for any operation on the part that comes out.

What is Plasma Cutting CNC Machine?

It is one of the most effective cutting methods. It is possible to cut almost any metal and alloy using this technique. Since plasma cutting of metal began to be used in industry not so long ago, all machines of this type have a modern design and are in most cases equipped with CNC.

Main advantages:

- High precision cutting,

- Ideal repeatability of all faces and dimensions of manufactured products,

- High cutting speed,

- Clean cut.